Heating plates

Heating plates are high-precision heating elements used in industrial applications that require precise temperature control, excellent heat resistance, and high thermal conductivity. The variations that are possible in size and wattage can reduce the number of heating plates required in an application. Heating plates are commonly found in semiconductor manufacturing, material processing, and high-tech laboratory environments.

Product summary

- Available in a range of materials and prices

- High precision heating

- Excellent thermal conductivity

- Kamet offers mica, metal and various ceramic heating plates

Different type of industrial heating plates

At Kamet we offer a range of heating plates with unique properties that can be matched to your particular application:

Mica heating plates – Are a low-cost, versatile solution at temperatures of up to 500 °C. They have a rapid response time, however they are mostly not reusable and can have issues with outgassing and low temperature uniformity.

Metal heating plates – For applications up to 400 °C, they are very durable with excellent temperature control. Moderately expensive with poorer heat transfer than ceramic plate heaters.

Ceramic heating plates – Ideal for very hot environments up to 1200 °C, these are the most expensive class of plate heaters with exceptional thermal performance and control as well as excellent durability.

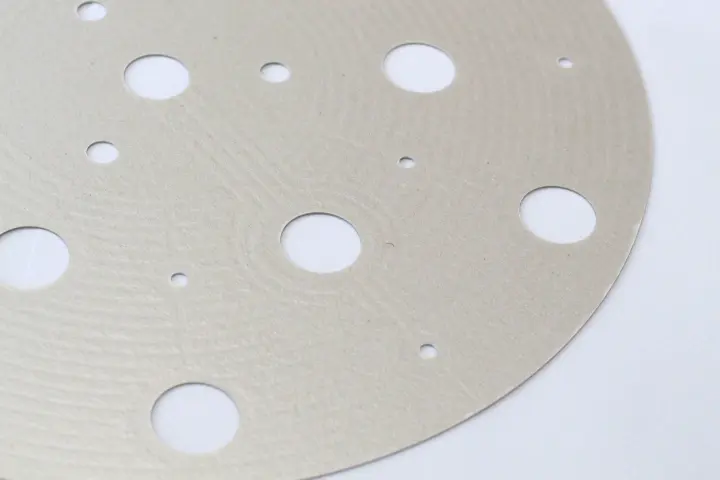

Mica heating plates

These heaters are made using a thin austenitic stainless steel heating element, which is either etched or compressed between layers of mica prepreg insulation (mica powder combined with a silicone binder). The mica layers provide excellent dielectric strength and heat resistance, ensuring efficient heat distribution while maintaining electrical insulation. The heater is securely clamped or bonded to a heat sink or application surface to maximize heat transfer and temperature uniformity. This thin and high-density design allows for rapid temperature changes, making it suitable for dynamic thermal processes.

Kamet has partnered with the long-standing Korean firm, SMG as supplier of high quality Mica heating plates with excellent reliability, while remaining as cost-effective as possible.

Specifications

- High temperature resistance in the range: -50 ~ 500°C

- Thin, lightweight with base thickness: 0.8mm ~ 2mm

- Size: 600mm × 500mm (custom sizes available)

- Maximum power density at 25°C in open air: 3W/cm2 (other power ranges are possible)

- Uniform heat distribution: (100°C): ±1°C

- Excellent Insulation: 1000V (60 sec)

- High insulation resistance 1000Ω (500V)

- Resistance tolerance ±10% based on room temperature

- Terminal handling: brazing

- Lead wire: horizontal or vertical withdrawal Option Connector

- Customizable: various sizes with different terminal and lead options.

Applications Mica heating plates

MICA plate heaters are widely used in applications that require fast, precise and reliable thermal management, including:

- Semiconductor industry – wafer heating and bonding processes to maintain controlled temperatures during production.

- Medical equipment – Integrated into laboratory devices, sterilization equipment, and diagnostic instruments.

- Military equipment – Applied in defense-related electronic and mechanical systems requiring stable and robust heating solutions.

Metal heating plates

Metal heating plates are resistant to high pressure and high temperatures and are very effective due to the excellent heat transference characteristics of the material. Our stainless steel heating plates are corrosion resistant and durable with excellent thermal conductivity.

Applications of metal heating plates span a range of industries. In components manufacturing, they help reduce soldering times, improving efficiency. The wood and paper industry uses them for processes such as lamination and the application of hot adhesives. In moulding and mould-making, including the production of polyurethane (PU) foam, thermal systems support consistent shaping and curing. The food and beverage industry benefits from their role in pasteurisation, fermentation, and ensuring optimal thermal energy transfer, all while upholding stringent hygiene standards.

Specifications

- Heater wire diameter: Ø0.8 < Ø3.2 with varying resistance values

- Insulation resistance: 1MΩ at 500V

- Withstand voltage: 1Kv/min

- Maximum operating temp: ~ 400°C

- Maximum product size: ~ 122 cm

- Maximum thickness: ~ 4T (four times the thickness of the heater wire)

- Input Voltage: changeable

Manufacturing Mica heating plates

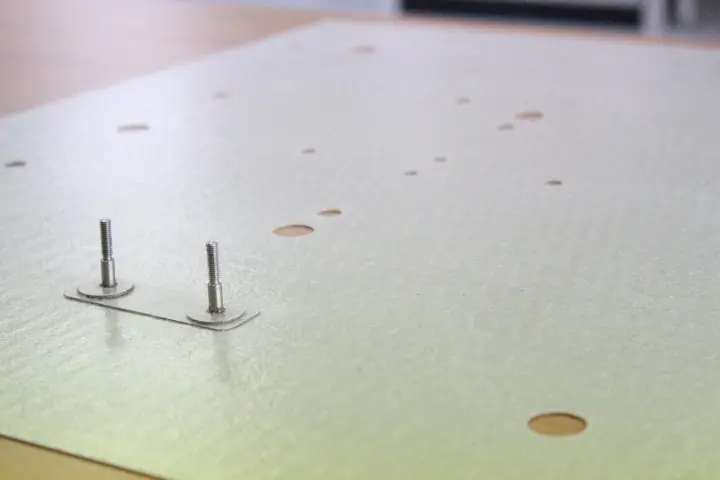

The design involves arranging our CVX heaters in a meandering pattern and then housing them in stainless steel. This is done either through vacuum brazing or by mechanically clamping them within the heating plate.

Vacuum brazing

This method involves arranging the CVX heaters in grooves or recesses in the metal plate. The entire assembly is placed into a vacuum oven that smelts soldering metal and thus bonds the heater and plate. This process offers the advantage of a good thermal coupling and a durable bond that is resistant to high temperatures and pressure. Heat transference is also improved due to the absence of air pockets in the structure.

Mechanical clamping

In the case of mechanical clamping, the CVX heaters are laid into especially etched grooves in the plate. The heaters are then clamped using the plate or a clamping construction. The advantage of this method is that it is much less technically complex than vacuum brazing. In addition, the heaters remain flexible and are easily detachable. The disadvantage of mechanical clamping is the thermal transfer is less efficient due to small air pockets being unavoidable in the structure.

The German company, ThermoExpert manufactures both types of metal heating plates for Kamet. They have decades of experience in providing reliable, quality products.

Ceramic heating plates

These heaters involve a ceramic heating element, often made of ceramic plates or coils, which heat up when an electric current passes through them. The properties depend on the materials used.

Kamet supplies all four types of ceramic heating plates through our partnership with the Korean company, SMG. Their quality, reliability and innovative approach ensures we offer ceramic heating plates of a high standard.

- Aluminum Nitride (AlN): excellent heat transfer, temperature uniformity and insulation.

- Silicon Nitride (Si₃N₄): good thermal shock resistance, mechanical strength and durability

- Quartz: high temperature and chemical resistance with exceptional purity.

- Alumina (Al₂O₃): can be cost-effective as well as offering good insulation and vacuum compatibility.

Specifications and applications

| Material | Thermal Conductivity | Maximum Temperature | Applications | |

|---|---|---|---|---|

| Aluminum Nitride (AlN) | 140-220 W/m.K | ~1000 °C | Vacuum environments as well as precision heating applications such as wafer processing (semiconductor industry) and DNA amplification (laboratory equipment). | |

| Silicon Nitride (Si₃N₄) | Lower than AIN | ~800 – 1000 °C | Harsh industrial environments, such as aerospace and petroleum and chemical works. | |

| Quartz | Moderate:~1.4 W/m.K | Very high: >1200 °C | Optical and laser industries and ultra high temperature applications. | |

| Alumina (Al₂O₃) | 20-30 W/m.K | ~1000 °C | Laboratory heating applications, semiconductor industries and vacuum processes. |

Kamet’s heating plates

Kamet works with SMG and ThermoExpert to supply this wide range of heating plates in the highest quality. We build on long-standing relationships with our manufacturing partners, thus ensuring we offer excellent quality, reliability and innovation to our customers.

Our team of specialists are on hand if you need any advice about the heating set-up best suited to your application/process. In addition, customization options for our heating plates can be discussed such as shape, size, voltage options, clamps or thermocouple holes. We look forward to hearing from you!

Reach out to us to discuss your specific needs

Contact our team today, and we help you in selecting the best products for your requirements.