What is Mineral insulated (MI) heating?

Certain heating applications are especially challenging. Mineral insulated heating has been designed to offer high watt density per square cm of surface area without loss of other performance characteristics. Furthermore, it offers a fast response time, long life time and the elements or cable can be readily bent by hand or production machinery to a desired configuration and retains that configuration after repetitive heating and cooling cycles.

Key benefits of MI heating

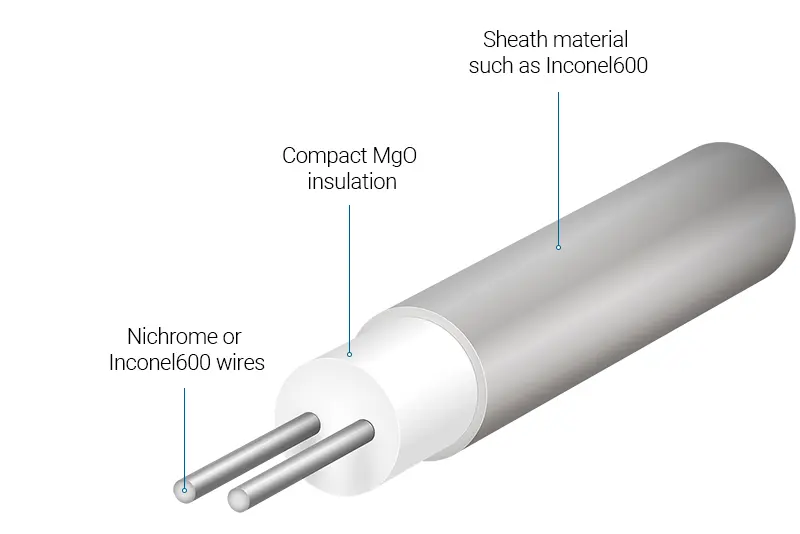

Mineral insulated heating is known for its exceptional durability and mechanical strength. An MI heating cable used to construct these type of heaters, consists of a high-resistance conducting wire in a metal sheath. A magnesium oxide (mineral) layer provides excellent insulation. These sheathed heating solutions can withstand high temperatures and pressures even in corrosive atmospheres. It is the heating solution of choice for applications where the required temperature and power output go beyond the specifications of self-regulating or constant-wattage cables.

Mineral insulated heaters have an excellent heat transfer and a constant power output, independent of temperature variations. Temperatures of up to 800 °C can be achieved in environments with an exposed temperature of up to 1000 °C.

- Exceptional durability and strength: Known for their high mechanical strength and durability, making them ideal for demanding environments.

- Excellent heat transfer: Provides constant power output independent of temperature variations, ensuring efficient heat transfer.

- Corrosion resistance: Sheath materials, like Inconel 600, Alloy 825, or stainless steel, offer resistance to corrosion, making it suitable for harsh environments.

- Versatile applications: Used in a variety of industries including aerospace, electronics, semiconductor and research institutes.

- Customizable specifications: Available in different resistance values and various lengths and diameters to match specific requirements.

- Insulation quality: Uses magnesium oxide for superior insulation, enhancing safety and performance.

- Precision heating: Offers precise temperature control with a range of conductor resistances, ensuring exact heat output

- Energy efficient: Provides consistent and reliable heating, improving energy efficiency in industrial processes.

Industrial heating: from single elements to complete solutions

What are mineral insulated heaters made off?

MI heaters are constructed with mineral insulated heating cables, which consist of one or two metal conductors, such as nickel or chromium, converting electrical energy into heat. The conductors are insulated with high quality magnesium oxide and covered with a heat, corrosion and pressure resistant metal sheath material, such as Inconel 600, Alloy 825, or stainless steel.

What is the size (length / diameter) of a mineral insulated heaters?

Our heaters are available in various lengths and diameters. In general, the length of the hot section of a micro heater starts around 100 mm. The maximum length is variable and depends on the sort of heater. For example, a heat tracing element can go up to 200 meters. The outside diameter of a heater can vary from 1.0 mm up to 13 mm.

How bendable are mineral insulated heaters?

They are highly bendable with a minimum bend radius of 5x the sheath diameter, allowing for easy installation and design flexibility.

Applications of MI Heating cable

Mineral insulated heating cable is a semi-finished product that can be used to make heat tracing cable, heating elements or micro heaters. Kamet also offers a range of these (customized) finished products. It is Kamet’s particular area of expertise: making our in-house knowledge and skills available to customers in order to come up with the heating product that perfectly matches the application.

Due to the variety of options for sheath material, they are suited for both hazardous and non hazardous applications. Furthermore, the range of conductor resistances allows precision adjustment to produce the exact heat required in any given application. Examples of industries that Kamet has supplied MI heating cable for include:

| Industry | Advantages of MI heaters | Known Uses |

|---|---|---|

| Aerospace | Can handle harsh environments, Small formed intricate geometries, Easy to braze |

Drain tubes, Pitot tubes, Ion propulsion cathode heater |

| Electronics | Small formed intricate geometries, Easy to braze |

Small heating plates for soldering/brazing |

| Semiconductor/Thin Film | Small formed intricate geometries, Easy to braze |

Wafer heater, Small/medium formed heater arrays |

| Research institutes | Small formed intricate geometries, Easy to braze, Can handle harsh environments |

Battery testing, Fluid tank level indicators/heaters, Ion propulsion cathode heater, Isotope seperator |

| Nuclear/powerplants | Small formed intricate geometries, Can handle harsh environments |

Off-site fire detector testers |

| Cryogenics | Small formed intricate geometries, Easy to braze | Cryopumps |

Our MI Heating Products

Application examples of MI heating cable

- Wrapped around an object

- Coiled inside an object

- (Vacuum) brazed on panel

- Fixed with welded brackets

- Held together by a clamp system

Sheath material options and their properties

There are many variables which make it possible to choose a mineral insulated heating cable that is a perfect match for your application. Below you can find the properties of sheath materials that are commonly used for mineral insulated heating cable.

| Inconel 600 -Nickel-chromium alloy | Alloy 825 -Nickel-iron-chromium alloy | Stainless steel alloys | |

|---|---|---|---|

| Temperature range | Cryogenic to 1000°C | Cryogenic to 500°C | Cryogenic to 800°C |

| Melting point | 1354°C – 1413 °C | 1370°C – 1400°C | 1400°C – 1455°C |

| General properties |

|

Cost-effective material: durable and long-lasting even at high temperature. Molybdenum contributes to exceptional hardness. |

|

| Corrosion resistance | High nickel content gives good resistance to:

The chromium provides resistance to sulfur compounds and oxidizing environments. Relatively unaffected by most neutral and alkaline salt solutions. Resistant to steam and mixtures of steam, air and carbon dioxide. |

Designed to offer excellent all-round corrosion resistance for most applications. | Stainless steel offers high corrosion resistance properties against a wide range of organic acids and alkalis. |

| Limitations | Not suited to reducing atmospheres, strong oxidizing solutions like hot, concentrated nitric acid. Inconel 600 has poor resistance. | Temperatures above 500°C can lead to microstructural changes that decrease strength and ductility. | Not all alloys are easy to weld. Stainless steel is more expensive than other alloys. |

| Application examples | Chemical and food processing, heat treating, phenol condensers, soap manufacture | Chemical processing, pollution control, oil and gas industry, acid production, nuclear power, and handling of radioactive wastes. | Automotive, aerospace and construction industries. |

Download the mineral insulated heating elements brochure

Consult this brochure for more information about our MI heating elements.

"*" indicates required fields

Okazaki Manufacturing company and ARi Industries

Kamet’s mineral insulated heating cables are produced by our long-standing partners, Okazaki Manufacturing Company and ARi Industries. With an annual capacity of 10.000 km, Okazaki offers a large production capacity. This, in combination with their operations excellence and 70+ years of experience, means our mineral insulated heating cables are ensured of the highest quality.

Additionally, Kamet also offers mineral insulated heating cables produced by ARi Industries. ARi Industries, located in the USA, is a leading supplier of customized mineral insulated cables and heating solutions.

Read more about Okazaki Manufacturing Company and ARi Industries.

Reach out to us to discuss your specific heating needs

Thermal challenges can be a complex business. Contact our in-house experts today and they will be able to clarify the range of mineral insulated heating solutions available to you.

What do our customers say about us?

We specialize in vacuum brazing of heating cables to stainless steel, copper and other alloys for components which on occasions are not serviceable items and hence the quality of the cables from a brazing perspective, workability, and performance with a long life expectancy of 7 to 10 years are critical. The quality of their heating cables is unparalleled, ensuring reliable performance and longevity even under the most demanding conditions especially in high vacuum and extreme temperature environments. The commitment to excellence throughout the supply chain which Kamet have established is evident in their premium products tailored to specific requirements of our most stringent quality control requirements.

Over the years Kamet have become a strategic supplying partner for us and we highly recommend them.

Highly recommended!

Kamet is well aware of its customers’ needs and has accompanied us through numerous projects. I enjoy working with them because they are responsive, everything is well organized, and they are all efficient and ready to help us.

They have developed their online portal, and I now have access to accurate information such as our prices, their stock and future deliveries, and values from certificates of calibration.

I highly recommend working with them.

Our wishes and suggestions are taken into account and if problems arise, we work together to find and implement a solution.

We look forward to many more years with Kamet as a business partner.