For reliable motor and generator monitoring

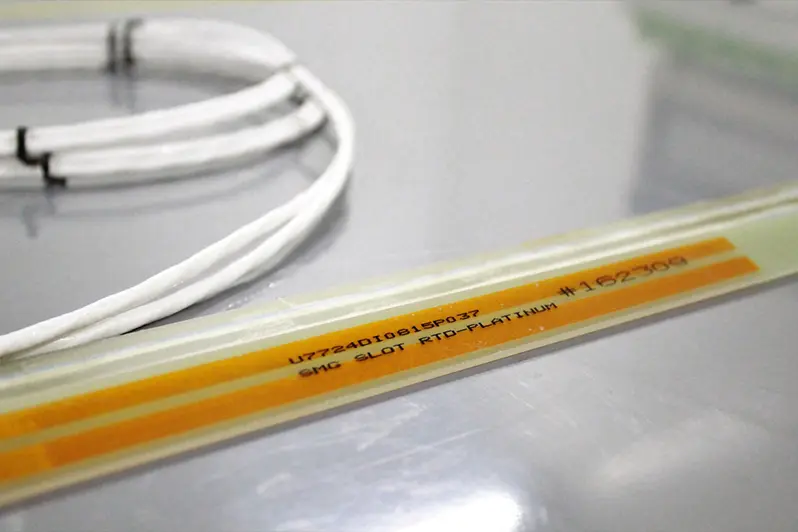

Stator Slot RTD sensor

Kamet supplies industrial-quality stator slot RTDs that are specifically designed to be installed between the stator windings of motors and generators. Also known as winding temperature detector (WTD). These resistance temperature detectors (RTDs) are essential for protecting high-value electrical machines from overheating, which can lead to insulation damage, system failure, and costly downtime.

The RTDs are embedded directly into the stator slots, in direct contact with the windings and insulation. This placement ensures highly accurate and localized temperature monitoring – a key factor in enhancing equipment reliability, performance and safety

Product summary

- Accurate temperature monitoring

- Enhances motor longevity

- Improves efficiency

- Early failure detection

- Ensures safety and cost savings

Stator slot applications across industries

Stator slot RTDs or winding temperature detector (WTD) are used across many sectors where reliable electric motors and generators are critical, including:

- Hydroelectric power stations

- Wind turbines

- Industrial manufacturing environments

- Heavy-duty electric machinery and generator systems

In all these applications, precise temperature monitoring leads to:

- Increased motor longevity

- Improved operational efficiency

- Early detection of faults or abnormal voltage conditions

- Enhanced safety during high-demand operations

- Reduced maintenance costs due to fewer insulation failures or mechanical breakdowns

Advanced design for industrial demands

Stator slot RTDs feature sensing elements along most of their length, allowing for continuous average temperature readings across a broad area. This design ensureslocalized hot spots are detected, providing a complete and responsive view of the thermal profile within the stator slot.

Our SMG stator slot RTDs are engineered to meet the demands of high-performance industrial environments. Key characteristics include:

- Flexible, non-inducible materials for optimal fit and performance

- Flat and thin design for seamless embedding between windings

- Bifilar construction to avoid induction-related errors

- Durability under shock, vibration, and pressure

- High accuracy, repeatability, and long-term stability

Custom solutions and precision with SMG

Our stator slot RTDs are manufactured by SMG in South-Korea. Trusted globally, SMG delivers high-performance thermal protection backed by proven Korean engineering. Most of their stator slot RTDs are delivered as custom-built solutions, tailored to the customer’s exact application and performance requirements.

Each sensor is calibrated and built to match your system requirements. Our engineers are happy to assist in selecting the best design for your application.

As an official distributor, Kamet is ready to support you in selecting the right stator slot configuration for your application.

Available specifications:

- Type of element: Pt100 (standard), Pt1000, Copper, Nickel, Type K thermocouple

- Single or duplex elements

- Lengths: 30 mm up to 5000 mm

- Thickness: typically between 1.3 and 2.0 mm

- Body with: depending on singel or duplex system

- Wire configurations: 2-, 3-, 4-, 6 or 8-wire systems

- Tolerance class Class A or B

- Hazardous area options: certified intrinsically safe and increased safety versions (ATEX, IECEx, KTL, KGS, BV Marine)

Let us help you find the best product

When doing business with Kamet, you can rely on fast and responsive customer service and consistent quality.

- Response time: within 24 hours on working days

- Delivery time: 3–4 weeks depending on design and configuration

Our team is ready to help you with technical advice, customization options, or quotations.