Ensuring reliable thermal protection in repaired motors

Motor repair and overhaul shops play a critical role in extending the service life of electric motors and generators used across industry and power infrastructure. During rewinding or major refurbishment, the stator winding and its insulation system are restored or replaced. Stator slot RTDs help ensure that the repaired machine can operate safely within its thermal limits, making accurate winding temperature measurement a major issue when returning equipment to service.

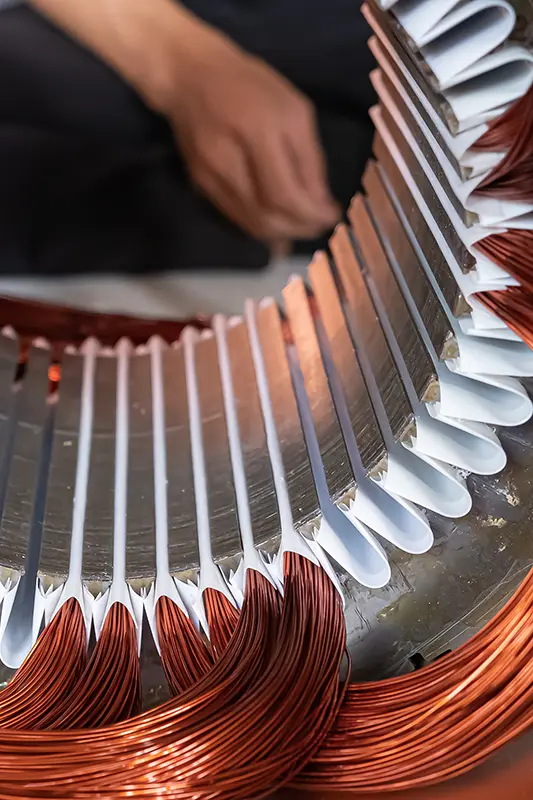

Temperature monitoring during rewinding

Stator slot RTD sensors are commonly installed or replaced during the rewind process, when stator slots are accessible. Their slim and laminated design allows them to be positioned directly alongside the new winding insulation without altering slot fill or electrical characteristics. For repair shops, this enables the restoration of original temperature monitoring capabilities or the upgrade of older machines that previously lacked direct temperature. By embedding stator slot RTD sensors, repair facilities ensure that temperature monitoring is an integral part of the rebuilt motor.

Supporting quality assurance and performance verification

After overhaul, motors are typically subjected to insulation resistance tests, surge tests, and heat run tests before release. Stator slot RTD sensors provide direct feedback on winding temperatures during these procedures, helping repair technicians verify that the insulation system perform as intended. Temperature data from stator slot RTDs can also be used to confirm that repaired machines meet customer specifications and applicable industry standards before shipment.

Reducing risk after return to service

Motors that have been rewound or repaired may operate in demanding environments with high loads or limited cooling. Stator slot RTDs supply continuous temperature information once the motor is back in operation, enabling operators to detect abnormal heating caused by installation issues, process changes, or cooling deficiencies. For repair shops, this added protection reduces the likelihood of early-life failures and costly rework.

Benefits for motor repair facilities

Including stator slot RTD sensors as part of a repair or overhaul offers several advantages:

- Restored protection: Re-establishes winding temperature monitoring that may have been lost or degraded over time.

- Enhanced reliability: Helps ensure repaired motors operate within safe thermal limits.

- Improved customer confidence: Demonstrates attention to long-term performance and protection.

- Lower callback rates: Early detection of thermal issues reduces premature failures after repair.

Typical repair and overhaul applications

Stator slot RTD sensors are widely used in repair shops servicing medium- and high-voltage motors, large low-voltage machines, and industrial generators. Common applications include motors for pumps, fans, compressors, mills, and conveyors. In each case, stator slot RTDs provide critical insight into winding temperature, helping repaired equipment return to service safely and reliably.

Download the stator slot RTD sensor leaflet

Download the stator slot RTD sensor leaflet for a quick overview of its added value, technical specifications, and typical applications.

"*" indicates required fields